Hydraulic control valves are integrated components in hydraulic methods, providing as the important thing regulators of fluid movement, pressure, and direction. These valves play a crucial position in a wide array of purposes, from industrial equipment and structure gear to aerospace and automotive systems. The simple concept behind hydraulic get a handle on valves lies in their ability to handle the flow of hydraulic substance within a program, enabling precise get a handle on and treatment of varied components.

One of many major features of hydraulic get a grip on valves would be to control the pressure inside a hydraulic system. Pressure get a handle on valves, such as relief valves, ensure that the stress remains within secure functioning restricts, avoiding potential injury to sensitive and painful components. That is very crucial in applications where maintaining a specific pressure level is crucial for optimum efficiency and safety.

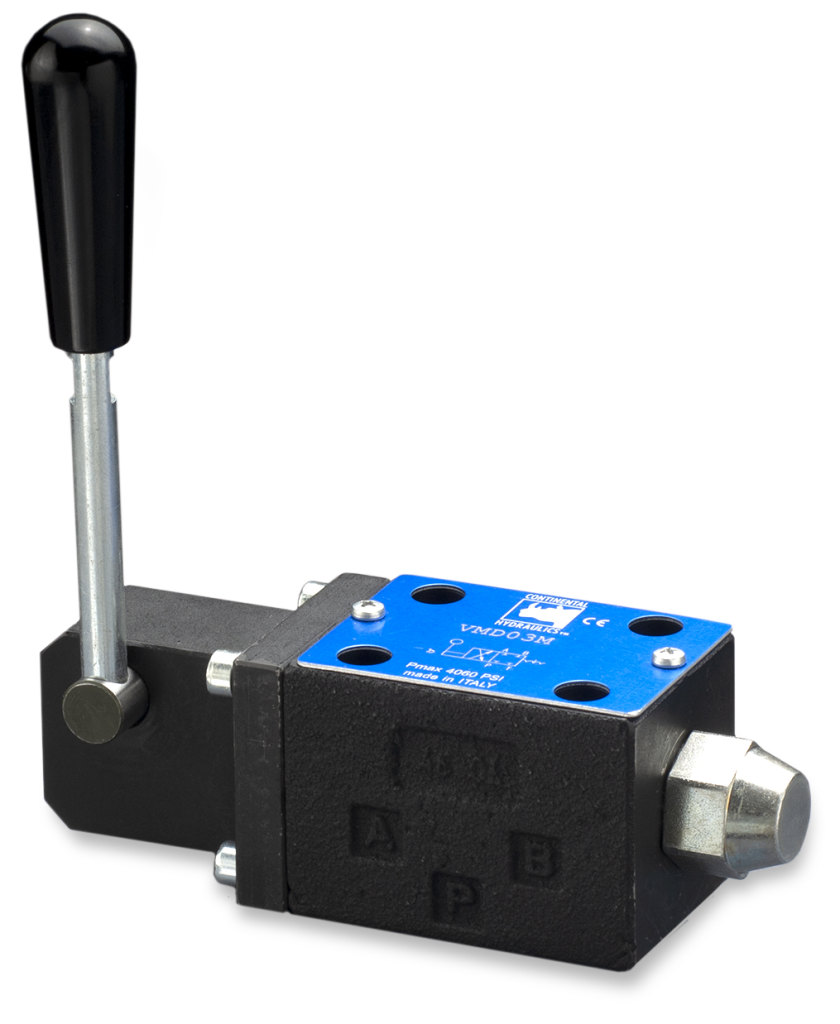

Directional control valves are yet another important sounding hydraulic get a handle on valves. These valves establish the path of fluid movement within the device, allowing the managed motion of hydraulic actuators. Whether it’s the expansion or retraction of a hydraulic cylinder or the rotation of a motor, directional control valves govern the trails whereby hydraulic water moves, dictating the motion of the related machinery.

Hydraulic get a handle on valves are made with many different get a handle on systems, including information, mechanical, and electro-hydraulic. Handbook valves enable hands-on get a grip on, technical valves respond to external causes or physical inputs, and electro-hydraulic valves leverage electrical signals for precise and automated control. That variety in get a handle on possibilities makes hydraulic techniques versatile to various working requirements and user preferences.

Effectiveness is just a important factor in hydraulic methods, and hydraulic control valves play a crucial role in optimizing performance. Proportional get a handle on valves, as an example, enable fine-tuned changes to liquid movement prices, permitting specific get a handle on over the speed and power of hydraulic actuators. That level of get a grip on improves overall system performance, minimizing energy spend and ensuring maximum operation.

In addition to their principal functions, hydraulic get a grip on valves contribute to system safety. Stress comfort valves behave as fail-safes, defending the system from overpressure and possible damage. The responsive character of those valves ensures that, in the case of a pressure spike, hydraulic fluid is diverted safely, avoiding catastrophic failures and safeguarding both the equipment and personnel.

The maintenance of hydraulic get a handle on valves is a must for sustained program performance. Normal inspections, washing, and lubrication are necessary to stop use and grab, escapes, and different conditions that may bargain the operation of the valves. Reasonable maintenance not only extends the life of the valves but additionally ensures the stability of the entire hydraulic system.

Invention in hydraulic get a handle on valve technology remains to improve, with the integration of digital and intelligent technologies. Electronic get a handle on models (ECUs) permit precise and programmable get a handle on around hydraulic systems, opening techniques for automation, distant tracking, and predictive maintenance. As industries transfer towards Industry 4.0, the position of clever hydraulic get a handle on valves becomes significantly essential in producing hydraulic control valves and smart hydraulic systems.

In summary, hydraulic get a grip on valves are the unsung heroes of hydraulic programs, giving the mandatory get a grip on and regulation for the effective function of varied machinery and equipment. Their versatility, accuracy, and share to system safety cause them to become essential in industries wherever hydraulic power is harnessed for an array of applications. As technology remains to advance, hydraulic get a grip on valves will likely play an even more innovative role in surrounding the ongoing future of hydraulic methods across varied sectors.